Table 6: General tolerances for symmetry (DIN ISO 2768 T2) The general tolerance for run-out and concentricity for class »K« is 0.2mm. In special cases for shape and position it is possible to choose tolerance class »H«. The general tolerance for run-out and concentricity for class »H« is 0.1mm.

According to DIN ISO 2768-1

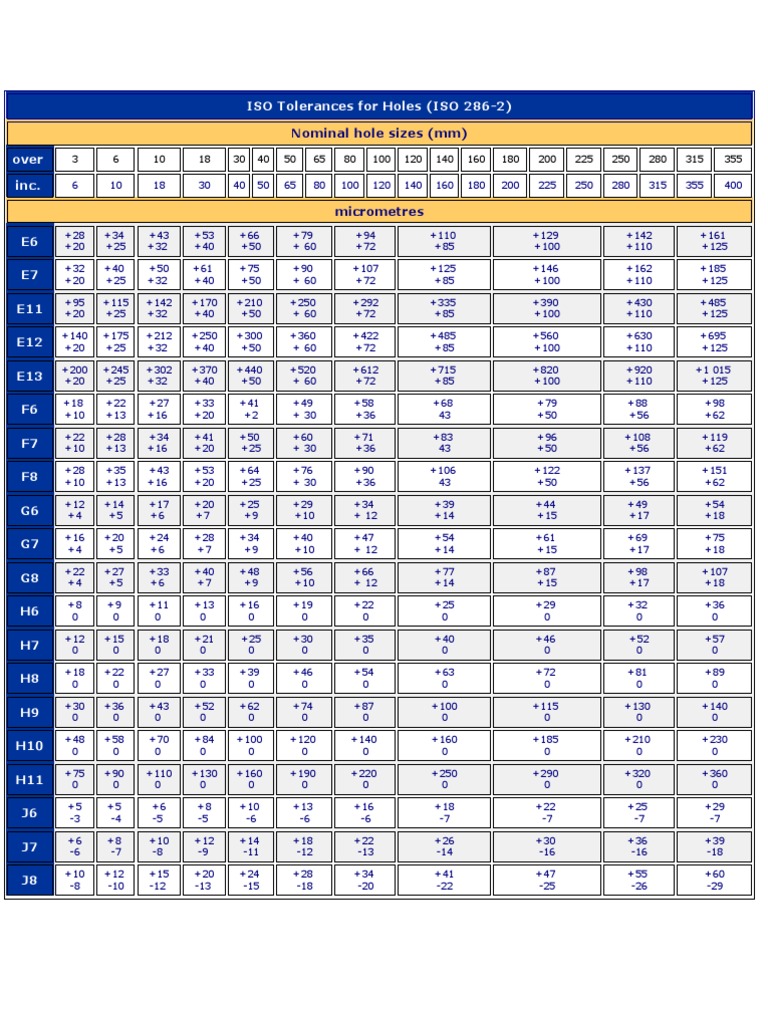

In this system of tolerances and fits, the upper deviation of the hole is always equal to: pin. Iso 2768 mk Tolerance Table images. All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials. Celestial Air Conditioner User Manual. Mar 25, 2009 Is the M6 hole tolerance also. ISO2768 has a sliding tolerance based on the size of the dimension. For a medium tolerance class per the ISO, dimensions over 6mm but up to 30 mm have a tolerance of +/.2mm. Dimensions above 120 but up 400 have a tolerance of +/.5mm. Therefore, the 200 dimension would have a tolerance of +/.5mm.

According to DIN ISO 2768-2

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.

By choosing the tolerance class precision levels common in workshops should be taken into account.

If smaller tolerances are needed or bigger ones are more economical,

then these tolerances are indicated next to the nominal size.

Tabular 1 Limits for linear measures

| Tolerance- class | Limits in mm for nominal sizes in mm | |||||||

0,5 to 3 | above | above 6 to 30 | above 30 to 120 | above 120 to 400 | above 400 | above 1000 | above 2000 | |

| f (fine) | ± 0,05 | ± 0,05 | ± 0,1 | ± 0,15 | ± 0,2 | ± 0,3 | ± 0,5 | - |

| m (medium) | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 |

| c (coarse) | ± 0,15 | ± 0,2 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 | ± 3 | ± 4 |

| v (very coarce grob) | - | ± 0,5 | ± 1 | ± 1,5 | ± 2,5 | ± 4 | ± 6 | ± 8 |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

Tabular 2 Limit measures for radius of curvature and chamfer height

| Tolerance class | Limits in mm for nominal sizes in mm | ||

0,5 to 3 | above 3 to 6 | above 6 | |

| f (finne) | ± 0,2 | ± 0,5 | ± 1 |

| m (medium) | |||

| c (coarse) | ± 0,4 | ± 1 | ± 2 |

| v (very coarse) |

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben.

Tabelle 3 Grenzabmasse für Winkelmasse

| Tolerance class | Limits in mm for nominal sizes in mm | ||||

to 10 | above 10 to 50 | above 50 to 120 | above 50 to 400 | above 400 | |

| f (fine) | ± 1 ° | ± 30 ' | ± 20 ' | ± 10 ' | ± 5 ' |

| m (medium) | |||||

| c (coarse ) | ± 1 ° 30 ' | ± 1 ° | ± 30 ' | ± 15 ' | ± 10 ' |

| v (very coarce) | ± 3 ° | ± 2 ° | ± 1 ° | ± 30 ' | ± 20 ' |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. If general tolerances according to ISO 2768-1 are valid,

the following has to be inserted in the title box, i.e. for tolerance class medium

ISO 2768 – m or general tolerance ISO 2768 – m

For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.

According to DIN ISO 2768-2

DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position.

By choosing a special tolerance class exactly the precision level common in workshops should be taken into account.

If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101.

General tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing.

This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 10 | above 10 to 30 | above 30 to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |

H | 0,02 | 0,05 | 0,1 | 0,2 | 0,3 | 0,4 |

K | 0,05 | 0,1 | 0,2 | 0,4 | 0,6 | 0,8 |

L | 0,1 | 0,2 | 0,4 | 0,8 | 1,2 | 1,6 |

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,2 | 0,3 | 0,4 | 0,5 | ||

K | 0,4 | 0,6 | 0,8 | 1 | ||

L | 0,6 | 1 | 1,5 | 2 | ||

| Tolerance class | General tolerances for symmetry | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,5 | |||||

K | 0,6 | 0,8 | 1 | |||

L | 0,6 | 1 | 1,5 | 2 |

General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually.

They are applicable for all characteristics of the form elements accept cylinders, profiles of any line or surfaces, inclines, coaxiality, position and total movement.

Ramo AB ansvarar ej för eventuella felaktigheter i ovanstående information.

Iso 2768 C

Ramo AB takes no responsibility in the eventuality of errors in the above information.

According to DIN ISO 2768-1

According to DIN ISO 2768-2

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.

By choosing the tolerance class precision levels common in workshops should be taken into account.

If smaller tolerances are needed or bigger ones are more economical,

then these tolerances are indicated next to the nominal size.

Tabular 1 Limits for linear measures

| Tolerance- class | Limits in mm for nominal sizes in mm | |||||||

0,5 to 3 | above | above 6 to 30 | above 30 to 120 | above 120 to 400 | above 400 | above 1000 | above 2000 | |

| f (fine) | ± 0,05 | ± 0,05 | ± 0,1 | ± 0,15 | ± 0,2 | ± 0,3 | ± 0,5 | - |

| m (medium) | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 |

| c (coarse) | ± 0,15 | ± 0,2 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 | ± 3 | ± 4 |

| v (very coarce grob) | - | ± 0,5 | ± 1 | ± 1,5 | ± 2,5 | ± 4 | ± 6 | ± 8 |

Iso 2768 Dimensional Tolerances

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.

By choosing the tolerance class precision levels common in workshops should be taken into account.

If smaller tolerances are needed or bigger ones are more economical,

then these tolerances are indicated next to the nominal size.

Tabular 1 Limits for linear measures

| Tolerance- class | Limits in mm for nominal sizes in mm | |||||||

0,5 to 3 | above | above 6 to 30 | above 30 to 120 | above 120 to 400 | above 400 | above 1000 | above 2000 | |

| f (fine) | ± 0,05 | ± 0,05 | ± 0,1 | ± 0,15 | ± 0,2 | ± 0,3 | ± 0,5 | - |

| m (medium) | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 |

| c (coarse) | ± 0,15 | ± 0,2 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 | ± 3 | ± 4 |

| v (very coarce grob) | - | ± 0,5 | ± 1 | ± 1,5 | ± 2,5 | ± 4 | ± 6 | ± 8 |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

Tabular 2 Limit measures for radius of curvature and chamfer height

| Tolerance class | Limits in mm for nominal sizes in mm | ||

0,5 to 3 | above 3 to 6 | above 6 | |

| f (finne) | ± 0,2 | ± 0,5 | ± 1 |

| m (medium) | |||

| c (coarse) | ± 0,4 | ± 1 | ± 2 |

| v (very coarse) |

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben.

Tabelle 3 Grenzabmasse für Winkelmasse

| Tolerance class | Limits in mm for nominal sizes in mm | ||||

to 10 | above 10 to 50 | above 50 to 120 | above 50 to 400 | above 400 | |

| f (fine) | ± 1 ° | ± 30 ' | ± 20 ' | ± 10 ' | ± 5 ' |

| m (medium) | |||||

| c (coarse ) | ± 1 ° 30 ' | ± 1 ° | ± 30 ' | ± 15 ' | ± 10 ' |

| v (very coarce) | ± 3 ° | ± 2 ° | ± 1 ° | ± 30 ' | ± 20 ' |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. If general tolerances according to ISO 2768-1 are valid,

the following has to be inserted in the title box, i.e. for tolerance class medium

ISO 2768 – m or general tolerance ISO 2768 – m

For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.

According to DIN ISO 2768-2

DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position.

By choosing a special tolerance class exactly the precision level common in workshops should be taken into account.

If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101.

General tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing.

This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 10 | above 10 to 30 | above 30 to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |

H | 0,02 | 0,05 | 0,1 | 0,2 | 0,3 | 0,4 |

K | 0,05 | 0,1 | 0,2 | 0,4 | 0,6 | 0,8 |

L | 0,1 | 0,2 | 0,4 | 0,8 | 1,2 | 1,6 |

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,2 | 0,3 | 0,4 | 0,5 | ||

K | 0,4 | 0,6 | 0,8 | 1 | ||

L | 0,6 | 1 | 1,5 | 2 | ||

| Tolerance class | General tolerances for symmetry | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,5 | |||||

K | 0,6 | 0,8 | 1 | |||

L | 0,6 | 1 | 1,5 | 2 |

General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually.

They are applicable for all characteristics of the form elements accept cylinders, profiles of any line or surfaces, inclines, coaxiality, position and total movement.

Ramo AB ansvarar ej för eventuella felaktigheter i ovanstående information.

Iso 2768 C

Ramo AB takes no responsibility in the eventuality of errors in the above information.

According to DIN ISO 2768-1

According to DIN ISO 2768-2

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.

By choosing the tolerance class precision levels common in workshops should be taken into account.

If smaller tolerances are needed or bigger ones are more economical,

then these tolerances are indicated next to the nominal size.

Tabular 1 Limits for linear measures

| Tolerance- class | Limits in mm for nominal sizes in mm | |||||||

0,5 to 3 | above | above 6 to 30 | above 30 to 120 | above 120 to 400 | above 400 | above 1000 | above 2000 | |

| f (fine) | ± 0,05 | ± 0,05 | ± 0,1 | ± 0,15 | ± 0,2 | ± 0,3 | ± 0,5 | - |

| m (medium) | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 |

| c (coarse) | ± 0,15 | ± 0,2 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 | ± 3 | ± 4 |

| v (very coarce grob) | - | ± 0,5 | ± 1 | ± 1,5 | ± 2,5 | ± 4 | ± 6 | ± 8 |

Iso 2768 Dimensional Tolerances

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

Tabular 2 Limit measures for radius of curvature and chamfer height

| Tolerance class | Limits in mm for nominal sizes in mm | ||

0,5 to 3 | above 3 to 6 | above 6 | |

| f (finne) | ± 0,2 | ± 0,5 | ± 1 |

| m (medium) | |||

| c (coarse) | ± 0,4 | ± 1 | ± 2 |

| v (very coarse) |

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben.

Tabelle 3 Grenzabmasse für Winkelmasse

| Tolerance class | Limits in mm for nominal sizes in mm | ||||

to 10 | above 10 to 50 | above 50 to 120 | above 50 to 400 | above 400 | |

| f (fine) | ± 1 ° | ± 30 ' | ± 20 ' | ± 10 ' | ± 5 ' |

| m (medium) | |||||

| c (coarse ) | ± 1 ° 30 ' | ± 1 ° | ± 30 ' | ± 15 ' | ± 10 ' |

| v (very coarce) | ± 3 ° | ± 2 ° | ± 1 ° | ± 30 ' | ± 20 ' |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. If general tolerances according to ISO 2768-1 are valid,

the following has to be inserted in the title box, i.e. for tolerance class medium

ISO 2768 – m or general tolerance ISO 2768 – m

For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.

According to DIN ISO 2768-2

DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position.

By choosing a special tolerance class exactly the precision level common in workshops should be taken into account.

If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101.

General tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing.

This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

Iso 2768 Hole Tolerance Table Top

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 10 | above 10 to 30 | above 30 to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |

H | 0,02 | 0,05 | 0,1 | 0,2 | 0,3 | 0,4 |

K | 0,05 | 0,1 | 0,2 | 0,4 | 0,6 | 0,8 |

L | 0,1 | 0,2 | 0,4 | 0,8 | 1,2 | 1,6 |

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,2 | 0,3 | 0,4 | 0,5 | ||

K | 0,4 | 0,6 | 0,8 | 1 | ||

L | 0,6 | 1 | 1,5 | 2 | ||

| Tolerance class | General tolerances for symmetry | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,5 | |||||

K | 0,6 | 0,8 | 1 | |||

L | 0,6 | 1 | 1,5 | 2 |

Iso 2768 Tolerances

General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually.

They are applicable for all characteristics of the form elements accept cylinders, profiles of any line or surfaces, inclines, coaxiality, position and total movement.

Ramo AB ansvarar ej för eventuella felaktigheter i ovanstående information.

Ramo AB takes no responsibility in the eventuality of errors in the above information.